Current Position: Index > Product > gate valve > Q347H/Y High pressure hard seal ball valve

Detailed introduction

Product Description

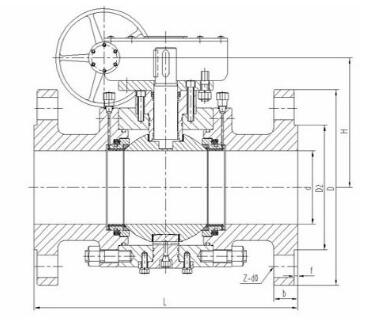

Q347H/Y turbo fixed high-pressure hard seal ball valve for long-distance pipeline and general industrial pipeline, its safety, resistance to harsh environments, etc. have been specially considered in the design, applicable to a variety of corrosive and non-corrosive media. It is compared with the floating ball valves, when working in the pipeline fluid pressure in front of the ball on the force generated by all transferred to the upper and lower bearings, the ball will not move, the valve sealing by the spring and the media pressure to promote the valve seat to achieve, and thus the valve seat will not withstand excessive pressure, so the fixed ball valve seat deformation is small, the operating torque is light, the sealing performance is reliable, and long service life. Especially suitable for high pressure, large diameter occasions. Design, manufacture and inspection are in accordance with the U.S. ASME and API standards, the appearance of the design of exquisite use of good results. Manual turbine, flange connection, fixed ball, valve body carbon steel or stainless steel, internal PTFE or alloy material seat, using temperature -196 ℃ +550 ℃ according to the sealing material selected for the medium: natural gas, water vapour, oil, acids, alkalis, and other types of media, the pressure level of 150LB ~ 1500LB. Widely used in natural gas pipeline, petrochemical water supply network and other industrial areas. and other industrial fields.

Scope of application.

Widely used in food, medicine, petroleum, chemical, natural gas, iron and steel, environmental protection, paper and other pipeline media cut off or flow.

Product features.

1、The valve seat adopts spring structure, which pushes the seat to the ball to ensure good low-pressure sealing performance.

2、Fixed ball valve valve before the valve, after the valve seat can be sealed, that is, the so-called two-way sealing characteristics, the use of self-contained discharge valve, the valve body cavity can be discharged to the outside.

3、The pivot adopts anti-blowout protection structure and low friction coefficient bearing. With excellent performance, high reliability and wide range of applications

Execution standard:

Design and manufacture: API 6D/API 608

Structure length: ASME B16.10

Flange standard: ASME B16.5/B16.47

Pressure test:API598/API6D/API600

Pressure and temperature: ASME B16.34

Product Performance Parameter: Q347H/Y turbine

Q347H/Y turbine fixed high-pressure hard seal ball valve performance parameters

pressure rating

| pressure rating(Class) | 150LB | 300LB | 600LB | ?900LB |

| Valve strength test pressure(Class) | 225LB | 450LB | 900LB | 1350LB |

| Valve sealing test pressure(Class) | 165LB | 330LB | 660LB | 990LB |

| Applicable temperature ℃ | ﹣20℃~350℃ | |||

| Main Material | ASTM A105 F304 F316 | |||

| Connection form | flangeless | |||

| Opening and closing form | manual turbocharger | |||

| Applicable medium | Water, gas, oil, etc. | |||

| connection standard | ASME B16.5 | |||

inch

| inch | 2″ | 21/2″ | 3″ | 4″ | 5″ | 6″ | 8″ | 10″ | 12″ | 14″ | 16″ | 18 | 20″ | 24″ | |

| d1 | 51 | 64 | 76 | 102 | 127 | 152 | 203 | 254 | 305 | 337 | 387 | 438 | 489 | 591 | |

| L | RF | 178 | 191 | 203 | 229 | 356 | 394 | 457 | 533 | 610 | 686 | 762 | 864 | 914 | 1067 |

| BW | 216 | 241 | 283 | 305 | 381 | 457 | 521 | 559 | 635 | 762 | 838 | 914 | 991 | 1143 | |

| H | 102 | 114 | 127 | 152 | 184 | 219 | 273 | 360 | 395 | 430 | 470 | 550 | 580 | 700 | |

| 手动 | H1 | 107 | 125 | 152 | 178 | 300 | 330 | 398 | 495 | 580 | 625 | 670 | 698 | 840 | 1050 |

| E | - | - | - | - | - | - | 116 | 116 | 171 | 171 | 257 | 257 | 257 | 150 | |

| F | - | - | - | - | - | - | 350 | 350 | 420 | 420 | 400 | 400 | 400 | 410 | |

| W | 230 | 400 | 400 | 650 | 1050 | 150 | 600 | 600 | 800 | 800 | 800 | 800 | 800 | 800 | |

| Wt(kg) | 12 | 16 | 22 | 35 | 58 | 74 | 205 | 322 | 576 | 576 | 864 | 1280 | 1600 | 3540 | |