一、固定球球阀密封原理

Fixed ball valve (Figure 1) opening and closing member is a ball with two support shaft, the middle of a channel equal to the diameter of the pipeline, on both sides of the two floating seat, the ball does not deviate from the axis of the support shaft on the ball rotation, the support shaft by the upper and lower two sliding bearing support, the valve seat is floating, the role of the media force, pushed toward the ball to produce a contact stress, in order to obtain a reliable seal. The same as the floating ball ball valve, the valve from open to close, or from close to open turn 90 ° angular stroke.

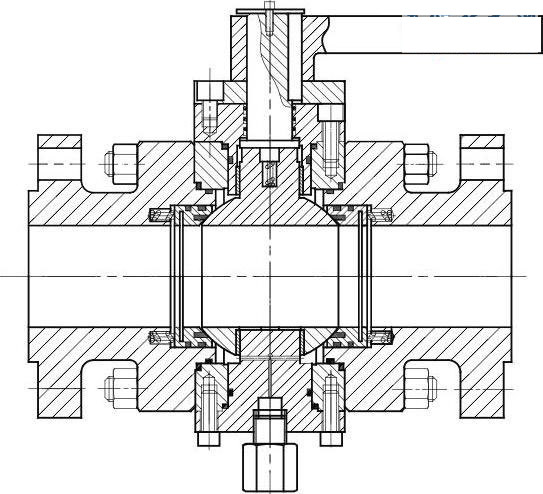

Fixed ball valve structure

Figure 1 Fixed ball valve structure

Second, fixed ball valve structure characteristics

Fixed ball valve valve body consists of the main valve body, the left and right two sub-bodies, the ball is a top end of the journal, the bottom end of the ball has a shaft hole, the upper part of the valve body there is a stuffing box, and the ball journal with a sliding bearing, the lower end of the ball body has a shaft hole, fitted with a sliding shaft bearing sleeve, the valve body has a bearing inserted into the lower end of the ball body shaft hole at the bottom. This way the ball is kept on the rotary centre line and will not be offset when rotating. There are two floating seat assemblies symmetrically on both sides of the ball, which are composed of a metal seat ring, a PTFE sealing ring set in the seat ring, a rubber O-ring on the outer edge and a coil spring on the back. When the valve is closed, the media force acts on the components of the sealing seat, so that the seat and the ball contact, resulting in contact stress, to obtain an effective seal. The valve stem and stuffing box body is sealed by O-shaped rubber ring.

Fixed ball valve structure than the floating ball ball valve is much more complex, the principle is that the media pressure to promote the seat assembly acting on the ball to produce contact stress to obtain sealing, the ball rotary centre axis does not shift, the valve seat assembly is floating, so it is called a fixed ball - floating seat structure. As the media force is acting on a ring area (Figure 3-14), the media thrust is much smaller than the floating ball valve media force, so the fixed ball valve structure is suitable for high-pressure large calibre, and its applicable range of pressure level Class150 ~ 2500, the valve diameter of NPS 2 ~ 60. For the use of PTFE, reinforced PTFE, nylon, PEEK and other polymer material For the use of PTFE, reinforced PTFE, nylon, PEEK and other polymer materials such as sealing ring structure, the design should still meet the sealing specific pressure q is greater than the necessary sealing specific pressure qb, less than the permissible specific pressure of the material [q], i.e. qb ≤ q ≤ [q].

It can be seen that, compared with the floating ball valve, the fixed ball valve features the following:

1)The size of the ball and seat combination is a free size, and not like the floating ball ball valve structure to form a closed size chain. Therefore, its sealing performance in the structure is not affected by temperature and pressure fluctuations;

2) is also the principle of media self-sealing, but the fixed ball valve media force is acting on the annular area of the valve seat, than the floating ball valve media force acting on the entire channel cross-section is obviously much smaller, and can be controlled through a reasonable design, so this structure is suitable for NPS 60 or less, the pressure level applies to all ball valve specifications below the Class2500, to become an important part of the development of ball valve Therefore, this structure is suitable for all ball valve specifications up to NPS 60 and pressure level up to Class2500, and it becomes an important structure form in the development of ball valve;

3) Based on the same reason as above, the operating torque of the ball valve is much smaller than that of the floating ball valve;

4) Its structure is more complicated than the floating ball valve, the weight is big, and the price is more expensive than the same specification floating ball valve;

5) Can be designed into full bore, standard bore and reduced bore, with larger flow capacity and lower flow resistance coefficient.