Pressure-Temperature Ratings for Body and Seat of Ball Valves

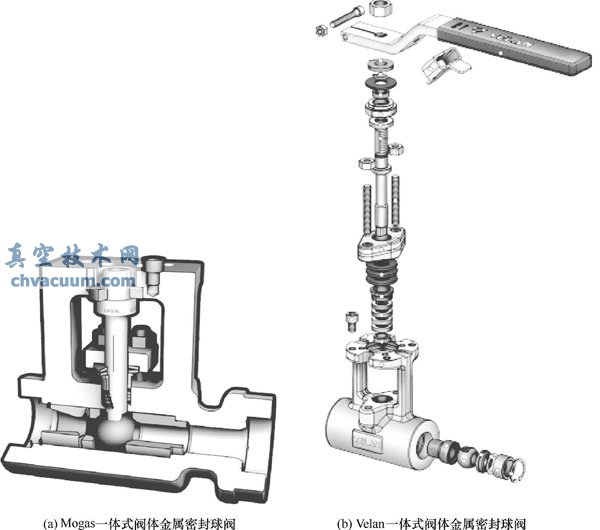

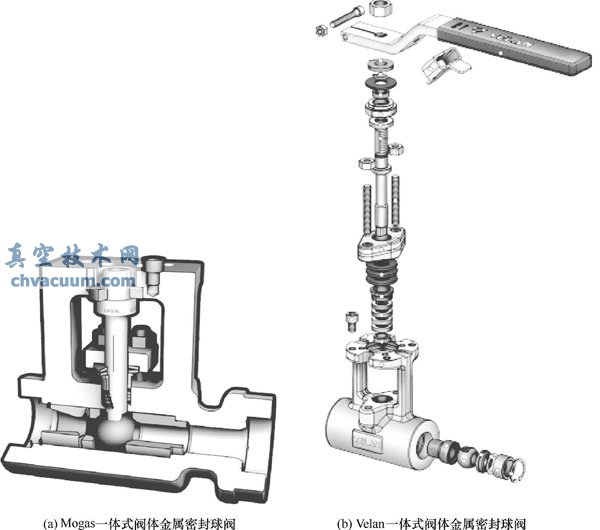

Mogas and Velan's metal-sealed ball valves offer a one-piece, drop-forged body construction that integrates the body with the operating mechanism's connecting support, and are available in pressure ratings up to 4,500 pounds and 1/2 to 2in diameters, for use as boiler traps and bypass isolation valves for electric power systems, in what Mogas describes as an innovative design in the RSVP series, which is illustrated in Fig. 1 for the Mogas product and the Velan product.

Figure 1 One-piece body metal sealed ball valve

Figure 1 shows that the sealing ball valve features: unidirectional sealing; integrated forging valve body design; the valve stem is loaded directly from the upper part of the valve body, at the upper end of the valve body, a thrust ring to prevent the valve stem from being blown out; packing with disc spring loading (living lead), to prevent thermal shock and pressure fluctuations caused by the relaxation of the filler; belongs to the floating ball structure, the outlet end of the sealing seat sealing, the inlet end of the seal seat Back with a spring made of Inconel material to provide a pre-tightening ratio pressure, and by the pipeline pressure to provide mechanical force to maintain a good sealing condition, in the upper part of the valve body design a 90 ° angle of the limit device, the ball and the seat of the paired grinding, 100% wide sealing band of the contact surface, to ensure that complete isolation, the sealing surface of the full-open positionwhen the sealing surface is protected, you can choose to use Inconel as a substrate material for the ball, and in the The surface is sprayed with chromium carbide coating to increase the resistance to abrasion and scouring.

The product sample material: ball for 410SS/HOVF chromium carbide or Inconel 718 body, HOVF chromium carbide coating, sealing seat material for 410SS + HVOF chromium carbide or Inconel 718 material, the valve body according to the different temperatures can be used for A182 F22, A105 or A182 F91 forgings, the valve stem using A276 Gr.431 nitriding The packing loading spring is Inconel 718, the packing sleeve is 316SS nitrided, the packing gland is 410SS, the packing is expanded graphite anti-squeeze ring with graphite + Inconel wire, and the non-return ring is A638660.